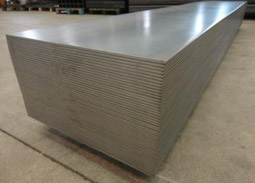

HEAVY – LTC PLUS

This is the evolution of the LTC line from which it differs, however, as a result of the technical features that make it possible to work thicknesses from 0.7 mm to 6.35 mm and coil widths up to 2,000 mm.

The PLC Plus has been designed for those who need continuous production changes with medium/high thicknesses and is characterized by notable structural features, rapid coil infeed changes and the maximum flexibility for machining:

– coils with widths of 1250, 1550 and 2050 mm

– thicknesses from 0.70 to 6.35 mm

– stainless steel from 0.50 to 5.0 mm

– production speeds up to 30 m/min.

LINE COMPOSITION

coil loading and coil infeed

specifically:

– coil car

– uncoiler

– snubber roll

– infeed table

straightening and measuring, cutting

specifically:

– straightener

– guillotine shear and/or circular blade shear

– scrap recoiler (option)

packing system

specifically:

– conveyor belt

– roller table

– stacker (manual or automatic)

Cutting line with start-stop operation*

Suitable for carbon steel, copper, small batches and frequent production changes. On request it can also be used for cutting stainless steel, and prepainted and aluminized materials.

Operation with loop*

It is particularly suitable for stainless steel and prepainted and aluminized materials as it protects the surfaces of the material from possible shadows due to start-stop operation.

Operation with flying shear*

Recommended for small spaces and continuous production with delicate materials such as stainless steel and prepainted and aluminized materials.

*The lines can by equipped with punching machines, cropping machines and stackers in accordance with specific needs and the solutions can also be diversified in accordance with machining needs. CAMU is able to ensure a painstaking study of the best solution and maximum flexibility of use.

Examples of application:

Italiano

Italiano